Manufacturing Process

Behind every Stone Age installation is a meticulous process that combines traditional craftsmanship with modern technology. From material selection through to final installation, our approach ensures every project meets our exacting standards.

Our Process

Consultation

Every project begins with a conversation. Our team takes the time to understand your vision in detail, whether it’s a single feature piece or a full property installation. We discuss your design preferences, practical requirements, and budget to ensure our proposals align with your expectations. This collaborative approach sets the foundation for a seamless journey from concept to completion.

Material Selection

Choosing the right stone is central to achieving a flawless finish. We provide expert guidance on material options, explaining the qualities, durability, and aesthetics of each stone. For clients seeking a more hands-on experience, we offer the opportunity to visit our suppliers and view slabs at source. This ensures you can see the natural variations and unique beauty of the stone before making a final choice.

Site Survey

Precision starts on-site. Our experienced surveyors carry out detailed measurements and carefully assess access points, ensuring every stage of installation can be completed smoothly. This step eliminates surprises later in the process and allows us to plan for exact stone dimensions, transportation requirements, and site-specific challenges.

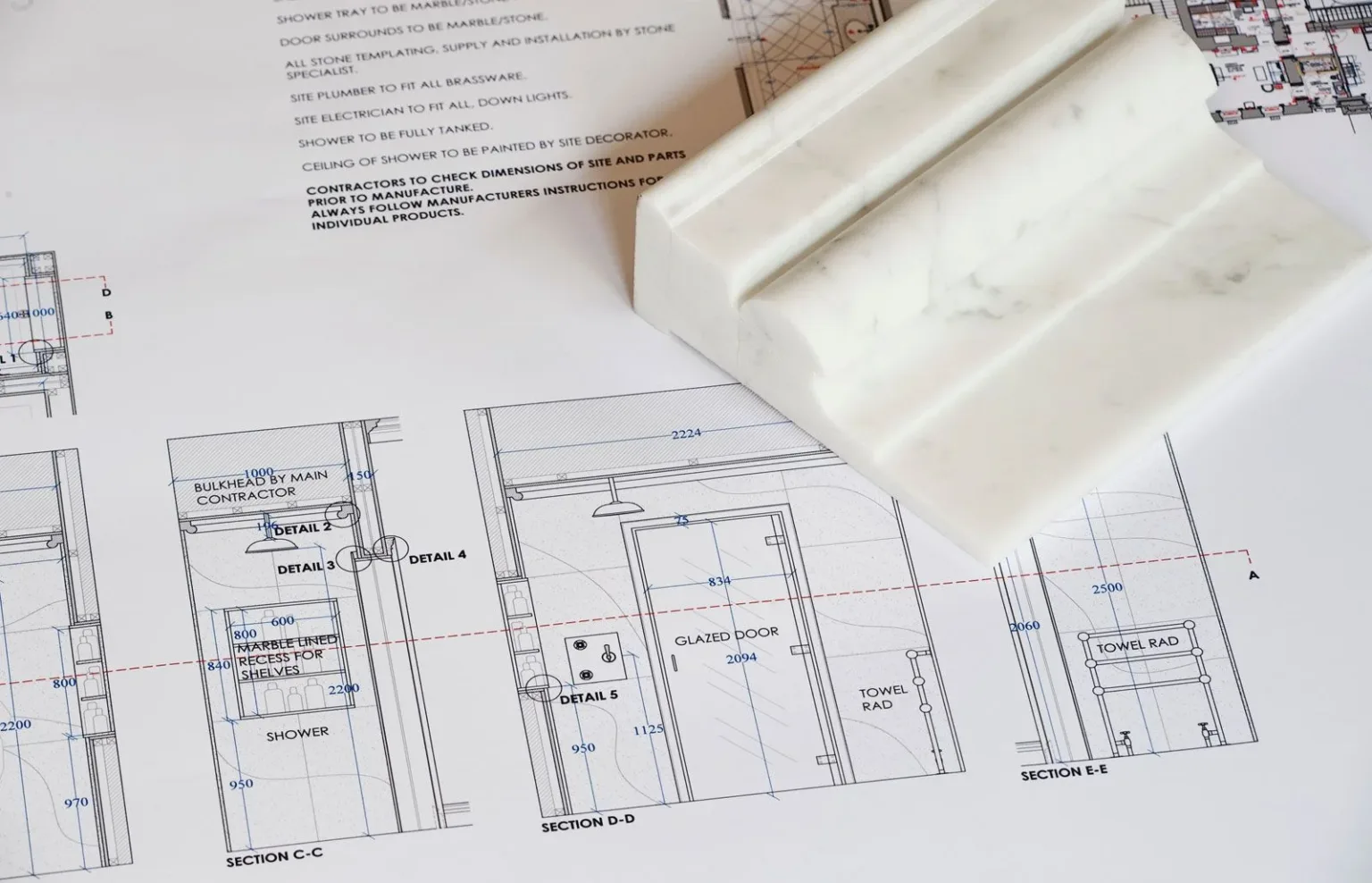

Drafting

Our in-house Draftsmen transform your requirements into accurate technical drawings. These detailed plans act as a blueprint for manufacture, giving you full visibility before production begins. Every element is measured and modelled to ensure a perfect fit. Draft drawings are reviewed and approved with you, so you can be confident that the finished result will meet your exact specifications.

Manufacture

Once approved, production begins in our Hertfordshire factory. Here, skilled stonemasons combine traditional craftsmanship with cutting-edge machinery to shape and finish your chosen slabs. From precise cutting and edge detailing to intricate shaping and polishing, every stage of manufacture is carried out with care and expertise. The result is a bespoke product tailored to your project’s unique design.

Quality Control

Before leaving our factory, every piece undergoes rigorous quality checks. We inspect the stone for consistency, structural integrity, and finish, ensuring it meets both our own exacting standards and your expectations. Only when a product passes this stage is it prepared for delivery, giving you complete confidence in the quality of the stonework.

Installation

Our installation teams bring the project to life on-site. With years of experience handling and fitting stone, they ensure each piece is installed with precision and attention to detail. From alignment and levelling to final finishing touches, the result is a flawless installation that enhances the beauty of your space and stands the test of time.

Why Choose Stone Age?

We combine technical expertise, a commitment to quality, and decades of experience to deliver stonework that stands the test of time. From one-off features to large projects, our manufacturing process ensures results that are both beautiful and practical.